From the Blog

Application of hinges and door closers 0

Taking into consideration that the hinges are manufactured to support a particular weight, for the proper operation, safety and longevity of the door, it’s necessary to consider several factors to apply the appropriate hinge.

The weight, width, and height of the door, frequency of use and any additional accessories installed are important factors to be taken into consideration when calculating the theoretical weight of the door or window.

Nevertheless, we strongly recommend a previous consultation whenever you have to apply hinges on doors or windows whose dimensions or weights are higher than normal. According to the EN 1935 standard, applied to single axis hinges, you should consider the following information:

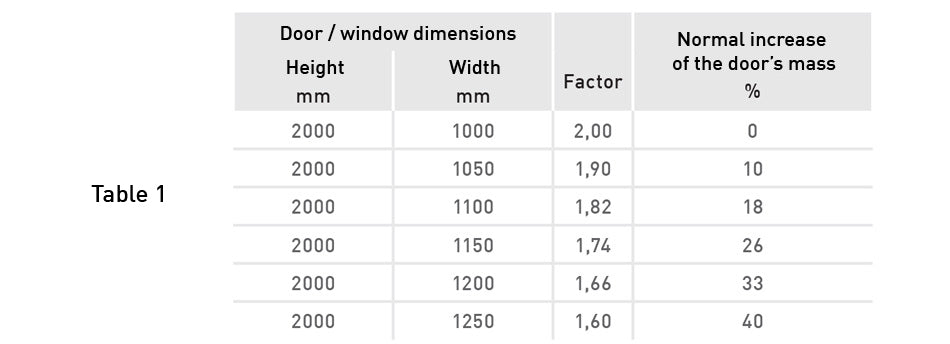

- Doors or windows with extra width see table 1

- Door closer application, consider +20% on the actual weight of the door

- Door closer application with hold-open or closing timer, consider +75% on the actual weight of the door

- The frequency of use or doors submitted to possible acts of vandalism are also factors to be considered when determining the type of hinge to apply.

For wide doors or windows, you must correct the mass to be supported by the hinges.

For doors or windows with constant height of 2000 and thickness up to 40 mm, the correction factors listed in table 1 should be considered.

Example: For a door with 50 kg of actual weight, 2000 of height and 1200 of width, add 33% = 66,5Kgs. When the factor obtained by dividing the height by the width is equal to or exceeds 2 (for example, 2000/900 = 2.22) no correction should be done.

It should be noted, however, that these calculations aren’t applied in spring hinges and pivot systems.

Application of hinges

In most cases, the door is supported by two hinges. However, we recommend you to use a third hinge to help stabilize the door, besides offering an increase of load capacity and longevity of its operation.

The application of a fourth hinge may be necessary for doors with a height higher than 2000mm or with excessive weight. In wooden doors with self-closing devices (door closers), at least three hinges should be applied, regardless of the weight and dimension of the door.

We recommend you to apply the hinges according to the following image.

Maintenance of hinges

We recommend a regular inspection and maintenance of the hinges (twice a year), specially in hinges applied to exit doors, in order to assure the perfect functioning of the panic / emergency devices.

Maintenance should include the appropriate lubrication and checking of the fixing points. The hinges applied to exterior doors require more frequent inspections due to its higher risk of corrosion.

We provide appropriate maintenance / cleaning products for corrosion points in Stainless Steel hinges.

If you have any question contact us, we are always here to help you!

- Team handlie

Doors and windows opening direction 0

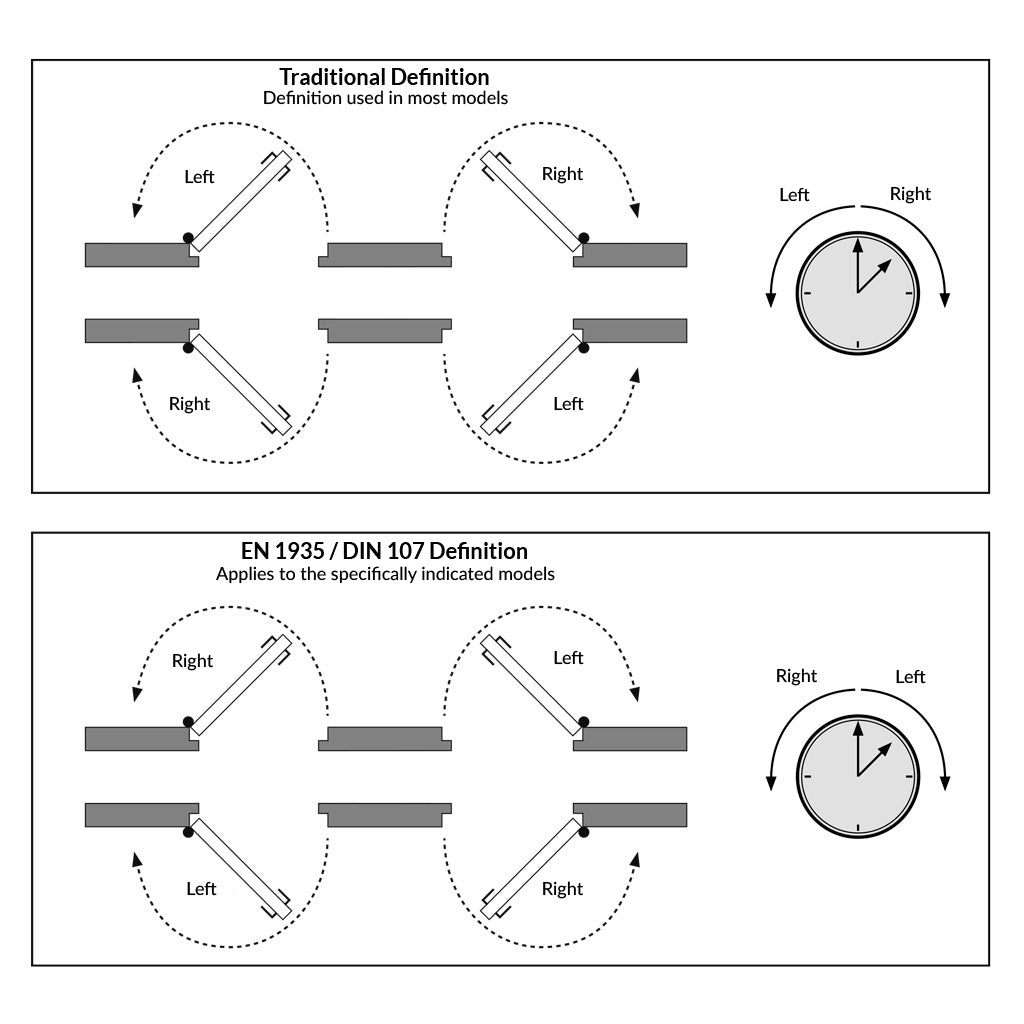

The two diagrams below should be read carefully, because to apply some models of hinges and locks it’s necessary to define in advance, according to the opening movement of the door or window, if they are RIGHT or LEFT.

Traditional Definition: Usually used in the portuguese market. It’s defined taking into consideration the opening movement, when pushing the door or opening in clockwise direction it's considered Right and in the opposite direction to clockwise Left.

EN 1935 / EN 12519 / DIN 107 Definition: These standards define that doors or windows opened in clockwise direction are considered Left and in the opposite direction to clockwise Right or according to the side the hinges are placed, taking into consideration the opening movement when pulling the door.

We use the TRADITIONAL definition in most of our hinges, taking into account the definition established in the market by the various agents of the sector. The models in which the standards EN 1935/EN/DIN 12519 107 are applied are specifically indicated.

If you have any question contact us, we are always here to help you!

- Team handlie

How to apply and maintain your hardware. 0

To keep the hardware at your house in good condition and to be able to preserve them for many years, we’d like to show you some information about its application, maintenance and conservation.

Stainless Steel Hardware

In general, the AISI 304 Stainless Steel is used for our stainless steel hardware. Some products may also be provided in AISI 316 Stainless Steel.

The main finish is in Satin Stainless Steel (brushed) and some models in Polished Stainless Steel.

The AISI 304 Stainless Steel alloy (also called 18.8 Stainless Steel) is the one that adapts most to the manufacturing of hardware for construction and furniture, because of its composition – Nickel Chrome Steel Alloy – and because besides its anticorrosive and aseptic characteristics it also offers a superior mechanical resistance.

The alloy designated as AISI 316 offers a superior resistance, being used in specific situations when the application is done in places with extremely adverse conditions.

The AISI 430 Stainless Steel alloy, also used in the manufacturing of some hardware, has a ferritic composition, so its application must take that into account.

The AISI 304 and 316 Stainless Steel have superior resistance, however to keep the product looking appealing it’s in your best interest to read carefully the following precautions:

- The hardware must be applied after the construction work is completed, specifically after the painting and treatment / varnishing of the woods.

- After the application of the hardware, acidic substances or substances that contain solvents shouldn’t be used in the cleaning of the floors or other areas of the construction because the vaporization of these products may cause damage.

- To clean you should never use steel or glass wool sponges because they may deposit residue that will later form corrosion points.

- Use nylon sponges and cloths moistened in water. Clean afterwards with a dry and soft cloth.

- The surface of the 304 or 316 Stainless Steel products is susceptible to attacks, leading to the potential appearance of red/ brown spots if constantly submitted to chemical agents, sea air, rain or other external agents. These spots should be avoided by being careful in the application and with regular maintenance / cleaning.

- In situations where a deep cleaning is needed, use appropriate products. In these cases, we'd appreciate your contact, since we provide cleaning, maintenance, reparation and protection products for Stainless Steel.

Brass, Aluminium and Zinc Alloy Hardware

Most of the finishes of these products are coated in a varnish or lacquer protecting layer applied by electrophoretic processes, for protection against corrosion, giving them a high resistance to abrasion and salt mist. To keep the original appearance, it’s extremely important to not damage the protecting layer, therefore, note the following precautions:

- The hardware must be applied after the construction work is completed, specifically after painting and treatment / varnishing of the woods. The chemical products to remove paint and varnish marks shouldn’t, in any case, be used because they damage the protecting layer, causing fast oxidation of the product.

- Acidic substances or substances that contain solvents shouldn’t be used in the cleaning of the floors or other areas of the construction because the vaporization of these products may cause damage in the protecting layer.

- To clean you should only use soft and dry cloths or lightly moistened in clean water.

Maintenance of hinges

We recommend a regular inspection and maintenance of the hinges (twice a year), specially in hinges applied to exit doors, in order to assure the perfect functioning of the panic / emergency devices.

Maintenance should include the appropriate lubrication and checking of the fixing points. The hinges applied to exterior doors require more frequent inspections due to its higher risk of corrosion.

We provide appropriate maintenance / cleaning products for corrosion points in Stainless Steel hinges.

If you have any question contact us, we are always here to help you!

- Team handlie